Various thin-film devices such as organic photovoltaics (OPV), light-emitting diodes, and display technologies require highly efficient electrodes to inject charge carriers into an active layer or to collect electrons and holes from charge-generating devices.

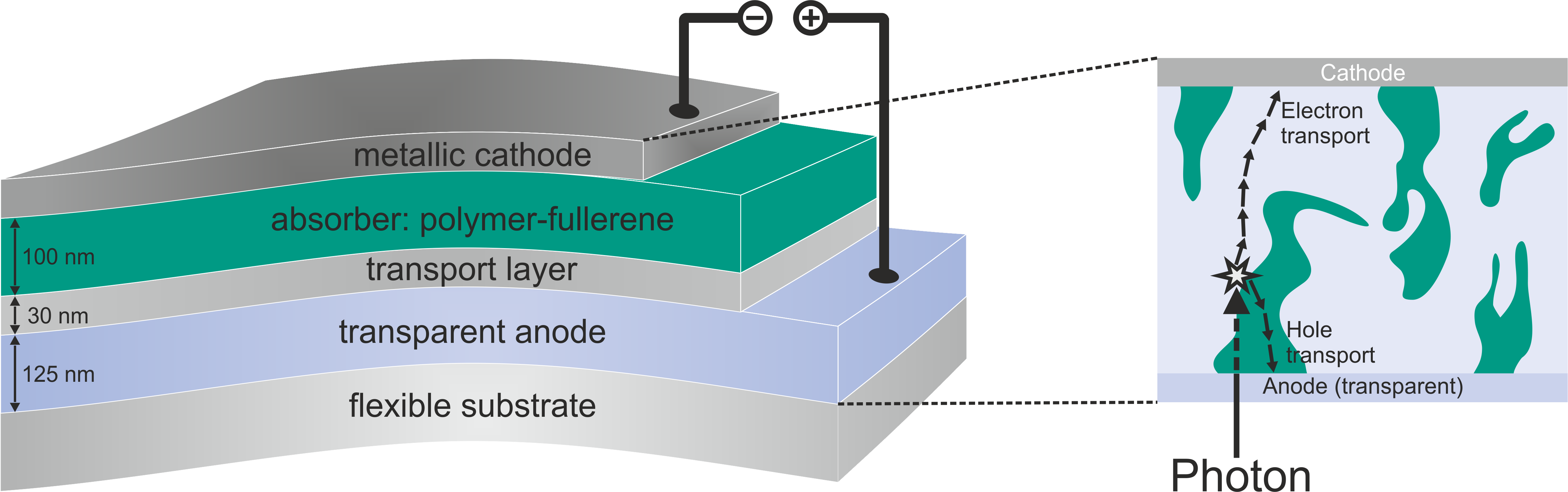

Fig. 1: Layered structure of an organic photovoltaic device. Charges are generated in the photoactive layer and must then be transferred to and subsequently along the electrodes.

Electrodes in organic photovoltaic devices must exhibit certain characteristics such as high conductivity across a large area, transparency for light transmission, and respective surface properties towards the layer that is cast on top. Additional transport layers, that are permeable for only one type of charge carriers, are often used in combination with electrodes and lead to higher efficiencies. Whereas solution-based deposition methods are well-established for the photoactive layer of organic solar cells, metallic electrode systems are mostly integrated into the device via cost-intensive vacuum-deposition steps. To further push these devices to large-scale roll-to-toll production, more research towards solution-processable electrodes is necessary.

Therefore this project aims for the development and optimization of new solution-processable electrode concepts. Based on different materials - as for example transparent conductive polymers and metallic grids - an optimal device morphology and structure must be developed. For an effective transfer from concept to large-scale roll-to-roll methods, different coating techniques such as slot-die coating, ink-jetting, doctor-blading, and gravure coating will be investigated.

Fig. 2: Left: Roll-to-Roll deposition techniques (here: slot-die coating), Right: Flexible electrode produced by ink-jet printing (picture by Ink-Tec).

This project is part of the research program "Organic Photovoltaics and Dye-sensitized solar cells" launched by the Baden-Württemberg Foundation. It is conducted in collaboration with the following partners:

• Light Technology Institute (LTI), Karlsruhe

• Institute for Nanotechnology (INT), Karlsruhe

• Institute for Inorganic Chemistry (AOC), Karlsruhe